Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-GC Three-Conductor Round Portable Power Cable, CPE Jacket 8kV ICEA S-75-381

Type SHD-GC Three-Conductor Round Portable Power Cable: High Voltage, Flexible, and Anti-Interference Solution for South Africa’s Mining and Heavy Industry

Type SHD-GC Three-Conductor Round Portable Power Cable, CPE Jacket 8kV ICEA S-75-381

Applications | These heavy duty cables are designed for applications such as longwall shearers, continuous miners and mobile equipment such as shovels, dredges and drills. |

Standards | ICEA S-75-381/NEMA WC 58 |

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Conductor Shield | Semi-conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting tape + Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene(CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×4 | 259 | 8 | 8 | 0.150 | 3.8 | 0.205 | 5.2 | 1.94 | 49.3 | 2308 | 3594 | 122 |

3×2 | 259 | 6 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.12 | 53.8 | 2920 | 4554 | 159 |

3×1 | 329 | 5 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.21 | 56.1 | 3292 | 5104 | 184 |

3×1/0 | 259 | 4 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.32 | 58.9 | 3675 | 5700 | 211 |

3×2/0 | 329 | 3 | 8 | 0.150 | 3.8 | 0.235 | 6.0 | 2.46 | 62.5 | 4304 | 6593 | 243 |

3×3/0 | 413 | 2 | 8 | 0.150 | 3.8 | 0.250 | 6.4 | 2.62 | 66.5 | 5200 | 7738 | 279 |

3×4/0 | 532 | 1 | 8 | 0.150 | 3.8 | 0.250 | 6.4 | 2.75 | 69.8 | 5840 | 8713 | 321 |

3×250 | 608 | 1/0 | 6 | 0.150 | 3.8 | 0.250 | 6.4 | 2.89 | 73.4 | 6774 | 9948 | 355 |

3×300 | 741 | 1/0 | 6 | 0.150 | 3.8 | 0.265 | 6.7 | 3.04 | 77.2 | 7423 | 11384 | 398 |

3×350 | 888 | 2/0 | 6 | 0.150 | 3.8 | 0.280 | 7.1 | 3.21 | 81.3 | 8543 | 12739 | 435 |

3×500 | 1221 | 4/0 | 6 | 0.150 | 3.8 | 0.295 | 7.5 | 3.56 | 90.4 | 11260 | 16757 | 536 |

In South Africa’s rugged mining and heavy industry landscapes, reliable power delivery is the backbone of operational success. From the depths of gold and platinum mines to the sprawling operations of heavy machinery in industrial hubs, the Type SHD-GC Three-Conductor Round Portable Power Cable with CPE Jacket (8kV) stands out as a critical component. Designed to withstand extreme conditions, these heavy-duty cables power equipment like longwall shearers, continuous miners, shovels, dredges, and drills.

What Are Type SHD-GC Portable Power Cables?

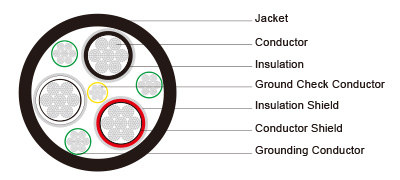

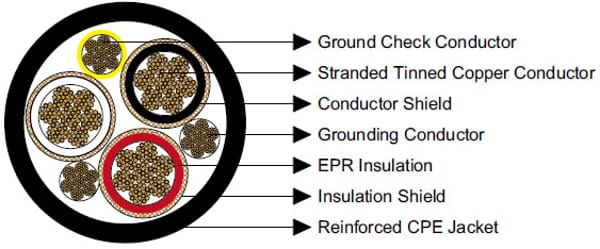

Type SHD-GC cables are engineered for high-voltage, heavy-duty applications in harsh environments. Certified to standards like ICEA S-75-381, NEMA WC 58, ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96, these cables are built for durability and safety. Their construction includes:

Conductors: Stranded annealed tinned copper for flexibility and conductivity.

Conductor Shield: A semi-conducting layer to manage electrical stress.

Insulation: Ethylene Propylene Rubber (EPR) for high dielectric strength and thermal resistance.

Insulation Shield: A combination of conducting tape and tinned copper/textile braid for enhanced protection.

Ground Check Conductor: Tinned copper with yellow polypropylene insulation for monitoring circuit integrity.

Grounding Conductor: Tinned copper for safe grounding.

Jacket: Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), with options for CSP, PCP, NBR, or PVC jackets. A two-layer jacket with reinforcing fiber is also available.

These cables operate at a maximum temperature of 90°C and have a minimum bending radius of six times the outer diameter (6×OD), ensuring flexibility in dynamic applications.

Benefits of Type SHD-GC Cables

Durability: The CPE jacket and reinforced construction resist abrasion, chemicals, and extreme temperatures, ideal for South Africa’s harsh mining conditions.

Safety: The ground check conductor ensures continuous monitoring of circuit integrity, reducing the risk of electrical faults.

Flexibility: A minimum bending radius of 6×OD allows these cables to navigate tight spaces in mobile equipment.

High Performance: EPR insulation and tinned copper conductors provide excellent conductivity and thermal resistance.

Customizability: Options for alternative jacket materials and two-layer designs cater to specific operational needs.

Installation Recommendations

Proper installation is critical to maximizing the lifespan and performance of Type SHD-GC cables:

Pre-Installation Inspection: Check for physical damage to the jacket, conductors, or insulation. Ensure the cable size matches the equipment’s power requirements.

Bending Radius Compliance: Maintain a minimum bending radius of 6×OD to prevent insulation or conductor damage.

Secure Connections: Use appropriate connectors and ensure tight, corrosion-resistant terminations.

Environmental Protection: In wet or corrosive environments, consider cables with alternative jackets like NBR or PVC for added resistance.

Cable Management: Use cable reels or supports to prevent excessive tension or kinking during equipment movement.

Maintenance Recommendations

To ensure longevity and safety, regular maintenance is essential:

Visual Inspections: Check for cuts, abrasions, or jacket wear monthly, especially in high-movement applications like continuous miners.

Electrical Testing: Periodically test insulation resistance and ground continuity to detect potential faults.

Cleaning: Remove dust, debris, or corrosive substances from the cable surface to prevent degradation.

Storage: Store unused cables in a dry, shaded area to avoid UV or moisture damage.

Repair or Replace: Replace cables showing significant wear or damage to avoid downtime or safety hazards.

Usage Scenarios in South Africa

South Africa’s mining sector, a cornerstone of the economy, relies heavily on robust power solutions. Type SHD-GC cables are ideal for:

Longwall Shearers: In coal and platinum mines, these cables power shearers that cut through tough rock, requiring high ampacity and flexibility.

Continuous Miners: Used in underground gold mines, these machines benefit from the cables’ durability and ground check features.

Mobile Equipment: Shovels and dredges in open-pit diamond mines depend on Type SHD-GC cables for reliable power during constant movement.

Drills: In heavy industries like steel production, these cables support high-power drilling operations.

Frequently Asked Questions (FAQ)

Q: What makes Type SHD-GC cables suitable for mining?

A: Their durable CPE jacket, EPR insulation, and ground check conductor ensure reliability, safety, and flexibility in harsh mining environments.

Q: Can these cables handle South Africa’s high temperatures?

A: Yes, they operate effectively up to 90°C, making them ideal for hot underground mines.

Q: How often should cables be inspected?

A: Monthly visual inspections and periodic electrical testing are recommended to ensure performance and safety.

Q: Are alternative jacket materials necessary?

A: In corrosive or wet environments, jackets like NBR or PVC may offer additional protection, depending on the application.

Q: What is the lifespan of Type SHD-GC cables?

A: With proper maintenance, these cables can last 5–10 years in demanding mining applications.

Type SHD-GC Three-Conductor Round Portable Power Cables are a game-changer for South Africa’s mining and heavy industry sectors. Their robust construction, high ampacity, and safety features make them indispensable for powering critical equipment in challenging environments. By adopting these cables, operators can enhance efficiency, reduce downtime, and meet stringent safety and sustainability standards. As South Africa’s mining industry navigates power challenges and global demand, Type SHD-GC cables offer a reliable, future-proof solution.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430