Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-GC Three-Conductor Round Portable Power Cable, TPU Jacket 2kV ICEA S-75-381

Discover Heavy-duty Cable Type SHD-GC for South Africa’s Mining and Heavy Industry

Type SHD-GC Three-Conductor Round Portable Power Cable, TPU Jacket 2kV ICEA S-75-381

Applications | These heavy duty cables are designed for heavy mobile equipment such as drag lines, shovels, dredges, drills and for power feeders. |

Standards | ICEA S-75-381/NEMA WC 58 |

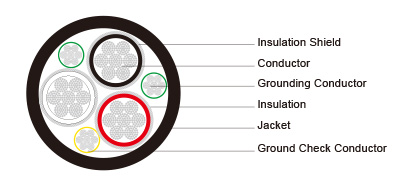

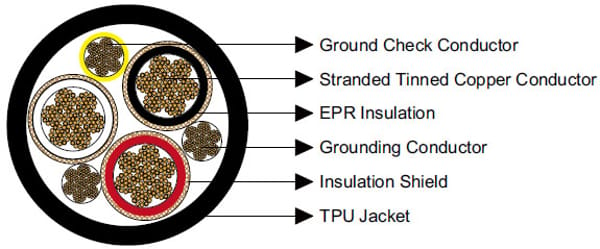

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Thermoplastic Polyurethane (TPU) Jacket, black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×6 | 133 | 10 | 10 | 0.07 | 1.8 | 0.155 | 3.9 | 1.29 | 32.8 | 1069 | 1590 | 93 |

3×4 | 259 | 8 | 10 | 0.07 | 1.8 | 0.155 | 3.9 | 1.40 | 35.6 | 1295 | 1927 | 122 |

3×2 | 259 | 6 | 10 | 0.07 | 1.8 | 0.170 | 4.3 | 1.59 | 40.4 | 1778 | 2645 | 159 |

3×1 | 259 | 5 | 8 | 0.08 | 2.0 | 0.190 | 4.8 | 1.76 | 44.7 | 2163 | 3218 | 184 |

3×1/0 | 266 | 4 | 8 | 0.08 | 2.0 | 0.190 | 4.8 | 1.86 | 47.2 | 2508 | 3731 | 211 |

3×2/0 | 323 | 3 | 8 | 0.08 | 2.0 | 0.205 | 5.2 | 2.00 | 50.8 | 3001 | 4465 | 243 |

3×3/0 | 418 | 2 | 8 | 0.08 | 2.0 | 0.205 | 5.2 | 2.13 | 54.1 | 3470 | 5163 | 279 |

3×4/0 | 532 | 1 | 8 | 0.08 | 2.0 | 0.220 | 5.6 | 2.31 | 58.7 | 4192 | 6237 | 321 |

3×250 | 627 | 1/0 | 6 | 0.095 | 2.4 | 0.220 | 5.6 | 2.51 | 63.8 | 5213 | 7756 | 355 |

3×350 | 888 | 2/0 | 6 | 0.095 | 2.4 | 0.235 | 6.0 | 2.81 | 71.4 | 6824 | 10153 | 435 |

3×500 | 1221 | 4/0 | 6 | 0.095 | 2.4 | 0.265 | 6.7 | 3.19 | 81.0 | 9014 | 13411 | 536 |

Understanding Heavy-Duty Cable Types

Heavy-duty cables are designed for demanding applications where standard cables would fail. The Type SHD-GC cable, for instance, is a three-conductor round portable power cable with a Thermoplastic Polyurethane (TPU) jacket, rated for 2kV, and compliant with standards like ICEA S-75-381, NEMA WC 58, ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96. These cables are tailored for heavy mobile equipment and power feeders in harsh environments.

Key Cable Types for Mining and Heavy Industry

Type SHD-GC: A three-conductor cable with a grounding conductor and ground check conductor, ideal for high-voltage mobile equipment in mining.

Type W: Single or multi-conductor cables for portable power applications, often used in less abrasive environments.

Type G-GC: Similar to SHD-GC but with additional grounding conductors for enhanced safety.

MP-GC (Mine Power Feeder Cables): Designed for stationary power distribution in mines, offering high durability and flexibility.

Each cable type serves specific purposes, with Type SHD-GC being particularly suited for South Africa’s mining sector due to its rugged construction and ability to handle extreme conditions.

Benefits of Type SHD-GC Cables

Durability: The TPU jacket and EPR insulation provide exceptional resistance to abrasion, chemicals, and extreme temperatures.

Flexibility: Stranded conductors and a minimum bending radius of 6×OD allow for easy maneuvering in tight spaces.

Safety: Grounding and ground check conductors ensure reliable grounding, reducing the risk of electrical faults.

Versatility: Suitable for a wide range of heavy equipment, from draglines to power feeders.

Customizability: Options for alternative jacket materials and two-layer designs cater to specific needs.

Frequently Asked Questions (FAQ)

What is the Type SHD-GC cable used for?

It’s designed for heavy mobile equipment like draglines, shovels, and drills in mining and heavy industry, as well as portable power feeders.

Why is the TPU jacket preferred?

TPU offers superior abrasion, chemical, and temperature resistance, making it ideal for harsh environments like South African mines.

How often should cables be inspected?

Inspect cables monthly in high-wear environments and quarterly in less demanding settings to catch issues early.

Can Type SHD-GC cables be customized?

Yes, options include alternative jacket materials (e.g., PVC, NBR) and two-layer designs for added durability.

What is the lifespan of a Type SHD-GC cable?

With proper installation and maintenance, these cables can last 5–10 years in demanding mining applications.

Are these cables compliant with South African regulations?

Yes, they meet international standards like ICEA S-75-381 and CAN/CSA C22.2 No. 96, aligning with South African mining safety requirements.

Heavy-duty cables like the Type SHD-GC are the backbone of South Africa’s mining and heavy industry sectors, powering critical equipment in some of the world’s toughest environments. Their robust construction, safety features, and versatility make them essential for ensuring operational efficiency and safety. By understanding their technical specifications, benefits, and best practices for installation and maintenance, industry professionals can optimize performance and reduce costs. As South Africa navigates challenges like load shedding and sustainability demands, these cables will continue to play a pivotal role in driving progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430