Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-PCG Three-Conductor Portable Power Cable 2kV ICEA S-75-381

Discover the Type SHD-PCG Portable Mining Power Control 2-In-1 Cable – Integrating Power and Control Conductors for Superior Performance in Strong Magnetic Fields

Type SHD-PCG Three-Conductor Portable Power Cable 2kV ICEA S-75-381

Applications | These heavy duty cables are designed for use on longwall shearers, where three shielded power conductors, three unshielded control conductors, and a grounding conductor are required. |

Standards | ICEA S-75-381/NEMA WC 58 |

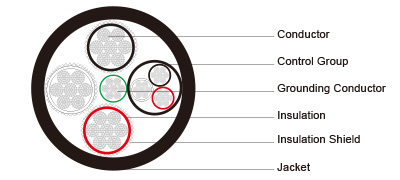

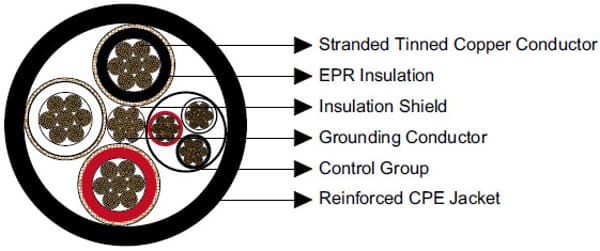

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Tinned copper/textile braid. |

Control Group (3 Conductor) | Tinned copper conductor, EPR insulation and thermosetting jacket. Colour of insulation: Black, white and red. |

Grounding Conductor | Tinned copper conductor, located in the center of the cable. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene(CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Control Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×1/0 | 259 | 3 | 8 | 0.08 | 2.0 | 0.205 | 5.2 | 2.05 | 52.1 | 3092 | 4602 | 211 |

3×2/0 | 329 | 2 | 8 | 0.08 | 2.0 | 0.220 | 5.6 | 2.25 | 57.1 | 3698 | 5503 | 243 |

3×3/0 | 413 | 1 | 8 | 0.08 | 2.0 | 0.220 | 5.6 | 2.32 | 58.9 | 4295 | 6392 | 279 |

3×4/0 | 532 | 1/0 | 8 | 0.08 | 2.0 | 0.250 | 6.3 | 2.62 | 66.5 | 5115 | 7612 | 321 |

In the high-stakes world of underground mining, where every second counts and safety is non-negotiable, the equipment that powers and controls massive machinery can mean the difference between seamless operations and costly downtime. Enter the Type SHD-PCG Portable Mining Power Control 2-In-1 Cable, a groundbreaking innovation that combines power and control conductors twisted together in a single composite cable. Designed specifically for harsh mining environments plagued by strong magnetic fields, this cable represents a leap forward in cable technology, offering enhanced anti-interference capabilities, durability, and efficiency. As mining operations worldwide grapple with escalating demands for sustainability, cost reduction, and technological integration, the SHD-PCG cable emerges as a vital tool, particularly in regions like South Africa, where the industry faces production challenges and innovation imperatives in 2025.

Benefits: Efficiency, Safety, and Cost Savings

The SHD-PCG's integrated design—twisting power and control conductors—minimizes cable clutter, simplifies routing, and reduces the risk of signal crosstalk in magnetic fields. Its anti-interference braided layer excels at shielding against EMI, ensuring stable transmission for critical operations like equipment monitoring.

Durability is a hallmark: The CPE jacket resists impacts, abrasions, and environmental stressors, extending service life in dusty, wet, or high-vibration settings. This translates to lower maintenance costs and fewer replacements, aligning with 2025 mining trends emphasizing cost-efficiency and profitability.

Safety benefits are profound. Grounding and shielding reduce electrical hazards, while the cable's flexibility (bending radius of 6×OD) allows safe installation around machinery. In strong magnetic fields, where instability could lead to accidents, the SHD-PCG provides reliable power to shearers, conveyors, and hydraulic systems, enhancing operational precision.

Installation and Maintenance Recommendations

Installing the Type SHD-PCG requires careful planning to maximize its benefits. Begin with a site assessment to identify magnetic hotspots and routing paths. Use cable reels for handling to prevent kinks, adhering to the 6×OD bending radius. Secure the cable with clamps every 1-2 meters in dynamic areas like longwall faces, ensuring slack for movement.

For connections, use compatible plugs and ensure proper grounding to avoid faults. In wet environments, apply sealants at junctions. Maintenance involves regular visual inspections for abrasion or jacket damage, especially in high-wear zones. Use multimeters to check continuity and insulation resistance quarterly. Clean with non-abrasive solutions, and store spares in cool, dry conditions. Following these steps can extend lifespan beyond 5-10 years in demanding setups.

Usage Scenarios: From Longwall to Heavy Industry

Primarily designed for longwall mining in coal extraction, the SHD-PCG powers and controls shearers, armored face conveyors, hydraulic roof supports, and ventilation systems. Its 2-In-1 design shines in confined underground spaces, where separate cables would complicate layouts.

Beyond longwall, it's adaptable to other mining scenarios, such as powering crushers or pumps in iron ore operations affected by magnetic fields. In heavy industry, it supports tunneling or quarrying equipment. For instance, in ventilation systems, stable control signals prevent downtime, crucial in oxygen-limited environments.

Feichun Cable: Pioneering Innovation

Developed by Feichun Cable in Hefei, China, the SHD-PCG reflects the company's commitment to excellence. Partnering with the University of Science and Technology of China, Feichun leverages advanced R&D for custom solutions. Their state-of-the-art facilities produce cables meeting international standards, with global reach ensuring availability for South African projects.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430