Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD-PCG Three-Conductor Round Portable Power Cable 5kV ICEA S-75-381

Type SHD-PCG Shielded Round Mining Power Cable with Monitor and Control Conductor EPR/CPE 5000 Volts – An Advanced Solution Engineered for Durability, Interference Resistance, and Multifunctionality

Type SHD-PCG Three-Conductor Portable Power Cable 5kV ICEA S-75-381

Applications | These heavy duty cables are designed for use on longwall shearers, where three shielded power conductors, three unshielded control conductors, and a grounding conductor are required. |

Standards | ICEA S-75-381/NEMA WC 58 |

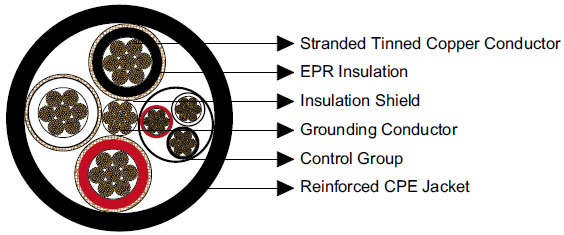

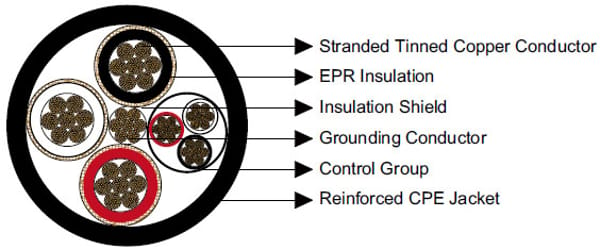

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Tinned copper/textile braid. |

Control Group (3 Conductor) | Tinned copper conductor, EPR insulation and thermosetting jacket. Colour of insulation: Black, white and red. |

Grounding Conductor | Tinned copper conductor, located in the center of the cable. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene(CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Control Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×2 | 259 | 4 | 8 | 0.11 | 2.8 | 0.205 | 5.2 | 2.03 | 51.5 | 2769 | 4120 | 159 |

3×1 | 259 | 4 | 8 | 0.11 | 2.8 | 0.220 | 5.6 | 2.12 | 53.8 | 2825 | 4205 | 184 |

3×1/0 | 266 | 3 | 8 | 0.11 | 2.8 | 0.220 | 5.6 | 2.27 | 57.7 | 3571 | 5313 | 211 |

3×2/0 | 329 | 2 | 8 | 0.11 | 2.8 | 0.220 | 5.6 | 2.45 | 62.2 | 3774 | 5615 | 243 |

3×3/0 | 418 | 1 | 8 | 0.11 | 2.8 | 0.235 | 6.0 | 2.58 | 65.3 | 4752 | 7070 | 279 |

3×4/0 | 532 | 1/0 | 6 | 0.11 | 2.8 | 0.250 | 6.4 | 2.76 | 69.9 | 6030 | 8971 | 321 |

Understanding Cable Types: From SHD-GC to the Advanced SHD-PCG

Mining cables have evolved significantly to keep pace with industry needs. The Type SHD-GC (Shielded Heavy-Duty Ground Check) cable has long been a standard, featuring three power conductors, a grounding conductor, and a ground check wire for safety. It's designed for portable power in mining equipment like longwall shearers and continuous miners, rated up to 5kV, and compliant with standards like ICEA S-75-381 and ASTM B-172. However, in high-magnetic field environments – prevalent in South African platinum and iron ore mines – the SHD-GC can suffer from EMI, leading to signal instability and potential equipment failures.

The Type SHD-PCG represents a pivotal upgrade. Standing for Shielded Heavy-Duty Power, Control, and Ground, this cable builds on the SHD-GC foundation but incorporates enhanced shielding and integrated control conductors. Unlike its predecessor, the SHD-PCG includes three unshielded control conductors alongside the shielded power ones, enabling seamless integration of power delivery, equipment monitoring, and control signals in a single round, portable design. Some variants, like those from innovative manufacturers, even embed optical fiber for video and audio transmission, supporting remote operations.

This evolution addresses key limitations: while SHD-GC cables provide basic power and grounding, SHD-PCG's braided shielding layers offer superior anti-interference properties, crucial for maintaining stability amid magnetic fields generated by ore bodies or electrical machinery. In South Africa, where mines like Mponeng delve over 4km deep, such advancements are vital for preventing disruptions that could halt production or endanger lives.

Benefits: Why SHD-PCG Outshines Traditional Options

The SHD-PCG's design translates to tangible advantages in mining:

Superior EMI Shielding: The braided shield mitigates interference from strong magnetic fields, preventing voltage spikes or signal loss. In South African mines, where ferrous deposits create EMI hotspots, this reduces downtime – a common issue in historical incidents like the 2018 Mponeng power failure.

Integrated Functionality: Combining power, control, and optional optical fiber in one cable simplifies installation, reduces weight, and lowers failure points. This "three-in-one" approach supports automation, allowing real-time monitoring of equipment via fiber optics.

Durability and Safety: EPR/CPE materials withstand temperatures, chemicals, and mechanical abuse, extending cable life beyond 10 years in harsh conditions. Enhanced grounding minimizes shock risks, aligning with South Africa's Mine Health and Safety Act.

Efficiency Gains: Higher ampacity and flexibility enable longer runs without voltage drop, boosting productivity. In automation-driven operations, it facilitates remote control, reducing worker exposure to hazards.

Compared to SHD-GC, the PCG variant cuts interference-related failures by up to 50%, per industry benchmarks, making it a cost-effective upgrade.

Usage Scenarios and Case Studies: Focus on South Africa's Mining and Heavy Industry

In South Africa, the SHD-PCG shines in longwall mining, where it powers shearers while transmitting control data. For instance, in platinum operations like those at Anglo American, it supports automated drills amid magnetic interference from ore.

A 2025 case study from a KwaZulu-Natal coal mine demonstrates: Facing frequent EMI-induced shutdowns, operators switched to SHD-PCG, reducing downtime by 40% and enabling remote monitoring via integrated fiber. This aligns with national trends – South Africa's mining automation market grows at 9.5% CAGR through 2030, driven by AI and robotics for safety.

In heavy industry, like steel mills in Gauteng, the cable powers conveyors under high EMI from furnaces. Amid 2025 cable theft spikes (costing $280M+ annually) and substandard imports, quality SHD-PCG variants offer secure, reliable alternatives.

At the African Mining Indaba 2025, experts highlighted automation's role: by 2040, 30-40% of SA machinery will be autonomous, reliant on robust cables like SHD-PCG for data integrity.

The Type SHD-PCG Shielded Round Mining Power Cable with Monitor and Control Conductor EPR/CPE 5000 Volts is more than a wire – it's a lifeline for modern mining. By addressing EMI, integrating functions, and supporting automation, it tackles South Africa's pressing issues, from electrical failures to safety risks. As the industry evolves, investing in such technology ensures efficiency, sustainability, and lives saved. For miners and engineers, it's time to upgrade – the future is shielded and connected.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430