Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type SHD Three-Conductor Flat Portable Power Cable 2kV -ICEA S-75-381

Type SHD Mining Trailing Flat Cable – Revolutionizing Durable Power Transmission in Harsh Mining Trailing Operations

Type SHD Three-Conductor Flat Portable Power Cable 2kV -ICEA S-75-381

Applications | These flat parallel cables are designed for use on continuous miners requiring grounding conductors and metallic shieldingover each conductor. |

Standards | ICEA S-75-381/NEMA WC 58 |

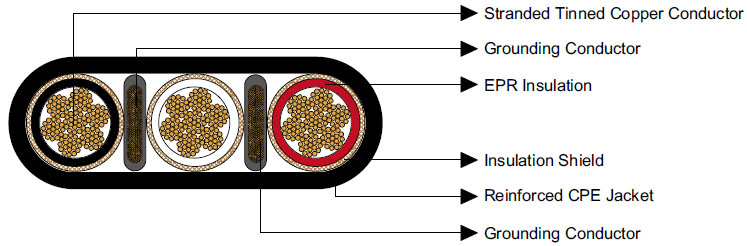

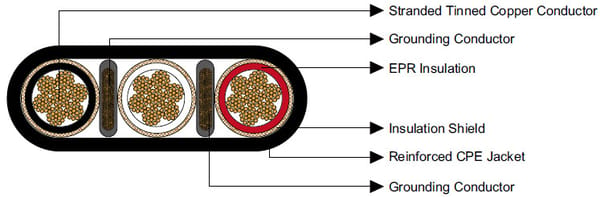

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Tinned copper/textile braid. |

Grounding Conductor | Tinned copper conductor covered with a conducting extrusion layer. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), black. |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Nominal Insulation Thickness | Nominal Insulation Thickness | Nominal Overall Diameter Height×Width | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×2 | 259 | 6 | 0.07 | 1.8 | 0.125 | 3.2 | 0.94×2.45 | 23.9×62.2 | 2243 | 3338 | 159 |

3×1 | 259 | 5 | 0.08 | 2.0 | 0.140 | 3.6 | 1.04×2.64 | 26.4×67.1 | 2540 | 3780 | 184 |

3×1/0 | 259 | 4 | 0.08 | 2.0 | 0.140 | 3.6 | 1.08×2.82 | 27.4×71.6 | 2915 | 4338 | 211 |

3×2/0 | 329 | 3 | 0.08 | 2.0 | 0.155 | 3.9 | 1.18×2.99 | 30.0×76.0 | 3346 | 4980 | 243 |

3×3/0 | 413 | 2 | 0.08 | 2.0 | 0.155 | 3.9 | 1.25×3.29 | 31.8×83.6 | 3890 | 5789 | 279 |

Understanding Cable Types: What Makes Type SHD Stand Out?

Cables in mining aren't one-size-fits-all; they vary based on voltage, construction, and application. The Type SHD (Shielded Heavy Duty) Mining Trailing Flat Cable is a subtype of portable power cables specifically engineered for trailing applications—where cables are dragged, bent, or twisted behind moving machinery like continuous miners or excavators.

At its core, the Type SHD is a three-conductor flat portable power cable rated for 2kV, distinguishing it from round cables by its flat design. This shape minimizes tangling and allows for better flexibility in confined spaces, ideal for mining trailing operations. Unlike standard power cables, which might use PVC insulation, the Type SHD employs Ethylene Propylene Rubber (EPR) for insulation, offering superior resistance to heat, moisture, and chemicals.

Key variants include:

Three-Conductor Configuration: Typically featuring power conductors, a grounding conductor, and metallic shielding over each conductor. This setup provides shock hazard protection and is compliant with standards like ASTM B172 for stranded copper conductors.

Flat vs. Round Designs: The flat parallel structure excels in applications requiring frequent reeling or unreeling, such as on mobile equipment, while round cables might be used in static setups.

Shielded Options: The insulation shield, often a tinned copper/textile braid, guards against electromagnetic interference (EMI) and induced voltages, crucial in environments with high electrical noise.

Compared to non-shielded cables like Type W, the SHD's shielding enhances safety in medium-voltage circuits (up to 2kV), making it indispensable where grounding systems could pose hazards. In essence, the Type SHD bridges the gap between rugged durability and precise power delivery, tailored for the dynamic demands of mining.

Benefits: Why Invest in Type SHD for Your Operations?

The Type SHD Mining Trailing Flat Cable delivers a trifecta of durability, efficiency, and safety, translating to tangible advantages in mining trailing operations.

Enhanced Durability and Longevity: Its rugged construction resists mechanical stress, abrasion, and environmental factors, outlasting standard cables by years. This reduces replacement frequency, cutting costs in high-maintenance sectors.

Improved Safety: Shielding and insulation minimize electrical faults, protecting workers from shocks or fires. In hazardous zones, this compliance with MSHA flame tests prevents accidents.

Operational Efficiency: High conductivity and flexibility ensure minimal power loss and easy handling, boosting productivity. The flat design fits tight spaces, ideal for mobile equipment.

Cost-Effectiveness: Lower maintenance needs and downtime make it a smart investment. For instance, its oil and chemical resistance prevents degradation in contaminated sites.

Versatility: Suitable for various setups, from conveyor systems to drilling machinery, with customizable jackets for specific needs.

Usage Scenarios: From Underground to Surface Mining

The Type SHD excels in diverse mining trailing operations:

Conveyor Systems: Powers belt conveyors in material handling, enduring constant movement.

Underground Mining: Trails behind continuous miners, providing shielded power in confined, damp tunnels.

Surface Operations: Supports rapid rail load-out stations, where speed demands reliable energy.

Drilling and Excavation: Energizes heavy machinery in open pits, resisting dust and vibration.

In Manually-Operated Wagon Loading Stations, it ensures precise chute control; in high-speed rail setups, it maintains uptime.

FAQ: Addressing Common Questions on Type SHD Mining Trailing Flat Cable

What is the main difference between Type SHD and Type G cables? Type SHD includes individual conductor shielding for better EMI protection, while Type G focuses on grounding without shielding.

Can Type SHD be used in non-mining applications? Yes, it's versatile for heavy industry like ports or construction, but optimized for mining trailing.

How does it handle extreme temperatures? Rated for -40°C to +90°C, with EPR insulation preventing brittleness or melting.

Is customization available? Options include alternative jackets (e.g., PVC) or reinforced layers for specific environments.

What standards ensure its safety? Compliant with ICEA S-75-381, ASTM B172/B33, and MSHA for flame retardancy.

How often should it be inspected? Quarterly in high-stress operations, or after incidents.

Empowering the Future of Mining with Type SHD

The Type SHD Mining Trailing Flat Cable isn't merely a wire—it's a lifeline for rugged power transmission in mining trailing operations. From its robust specs and safety features to real-world wins in South Africa's challenging landscape, it embodies innovation in cable technology. As industries grapple with sustainability and efficiency, investing in such durable solutions ensures operations thrive. Whether you're upgrading a wagon loading station or drilling in harsh terrains, Type SHD delivers reliability that powers progress. Embrace this American-standard marvel and elevate your mining game today.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430