Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type W Four-Conductor Flat Portable Power Cable 2kV

Exploring Type W Four-Conductor Flat Portable Power Cables for South Africa’s Mining and Heavy Industry Applications

Type W Four-Conductor Flat Portable Power Cable 2kV

Applications | These flat parallel cables are designed for use on ACmining equipment, such as A.C. shuttle cars, drills, cutting and loading machines |

Standards | ICEA S-75-381/NEMA WC 58 |

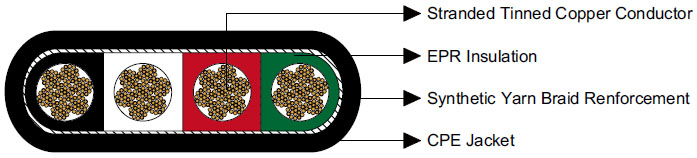

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Reinforcement | Synthetic yarn. |

Jacket | Heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

4×6 | 133 | 0.06 | 1.5 | 0.095 | 2.4 | 0.67×1.69 | 17.0×42.9 | 895 | 1332 | 72 |

4×4 | 259 | 0.06 | 1.5 | 0.110 | 2.8 | 0.75×1.89 | 19.0×48.0 | 1185 | 1764 | 93 |

4×2 | 259 | 0.06 | 1.5 | 0.110 | 2.8 | 0.84×2.23 | 20.6×56.6 | 1620 | 2411 | 122 |

4×1 | 259 | 0.08 | 2.0 | 0.125 | 3.2 | 0.97×2.60 | 24.6×66.0 | 2100 | 3125 | 143 |

4×1/0 | 259 | 0.08 | 2.0 | 0.140 | 3.6 | 1.01×2.73 | 25.7×69.3 | 2500 | 3721 | 165 |

4×2/0 | 329 | 0.08 | 2.0 | 0.140 | 3.6 | 1.10×2.96 | 27.9×75.2 | 2900 | 4316 | 192 |

4×3/0 | 413 | 0.08 | 2.0 | 0.155 | 3.9 | 1.18×3.25 | 30.0×82.6 | 3500 | 5209 | 221 |

4×4/0 | 532 | 0.08 | 2.0 | 0.155 | 3.9 | 1.29×3.46 | 32.8×87.9 | 4225 | 6288 | 255 |

In the heart of South Africa’s mining and heavy industry sectors, where rugged environments and demanding conditions are the norm, reliable power distribution is critical. Type W Four-Conductor Flat Portable Power Cables, designed for 2kV applications, are engineered to meet these challenges head-on. These cables are a cornerstone for powering heavy machinery such as AC shuttle cars, drills, and cutting and loading machines in mining operations. This article explores the technical specifications, benefits, installation and maintenance recommendations, usage scenarios, and real-world case studies, particularly in the context of South Africa’s mining and heavy industry sectors. We’ll also address frequently asked questions (FAQs) to provide a comprehensive guide for professionals and decision-maker

What Are Type W Four-Conductor Flat Portable Power Cables?

Type W Four-Conductor Flat Portable Power Cables are specialized cables designed for alternating current (AC) mining equipment. Their flat, parallel configuration distinguishes them from round cables, offering unique advantages in flexibility and space efficiency. These cables are built to withstand harsh environments, including extreme temperatures, abrasion, and mechanical stress, making them ideal for South Africa’s mining operations in regions like the Witwatersrand Basin or the Bushveld Complex.

Key Features

Voltage Rating: Rated for 2kV, suitable for high-power applications.

Conductor Configuration: Four stranded annealed tinned copper conductors for enhanced conductivity and corrosion resistance.

Insulation: Ethylene Propylene Rubber (EPR) for superior thermal and electrical properties.

Jacket: Heavy-duty or extra-heavy-duty Chlorinated Polyethylene (CPE), with optional materials like CSP, PCP, NBR, or PVC.

Reinforcement: Synthetic yarn for added tensile strength.

Standards Compliance: Meets ICEA S-75-381/NEMA WC 58, ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96 standards.

The flat design minimizes tangling and allows for easier handling and installation in confined spaces, a critical feature for underground mining operations.

Benefits of Type W Four-Conductor Flat Portable Power Cables

The unique design and robust construction of Type W cables offer several advantages for South Africa’s mining and heavy industry sectors:

Enhanced Durability: The heavy-duty CPE jacket and synthetic yarn reinforcement ensure longevity in abrasive and high-stress environments, such as underground mines or heavy industrial plants.

Space Efficiency: The flat configuration reduces the space required for installation, making it ideal for cramped mining tunnels or equipment setups.

High Flexibility: A minimum bending radius of 6×OD allows for easy maneuvering around obstacles, reducing installation time and costs.

Corrosion Resistance: Tinned copper conductors prevent oxidation, ensuring reliable performance in humid or chemically aggressive environments.

Versatility: Customizable jacket materials and optional two-layer designs cater to specific operational needs, such as extreme temperatures or chemical exposure.

Safety and Compliance: Adherence to international standards ensures safe operation, reducing the risk of electrical faults or downtime.

Usage Scenarios in South Africa’s Mining and Heavy Industry

Type W Four-Conductor Flat Portable Power Cables are widely used in South Africa’s mining and heavy industry sectors, where reliable power is essential for operational efficiency.

Underground Mining

In the gold and platinum mines of the Witwatersrand Basin and Bushveld Complex, these cables power AC shuttle cars and drilling equipment. Their flat design allows for easy routing through narrow tunnels, while the durable CPE jacket withstands constant abrasion from rock surfaces.

Surface Mining

In open-pit coal mines in Mpumalanga, Type W cables supply power to large loading machines and conveyors. The cables’ flexibility and high ampacity ensure uninterrupted operation, even under extreme heat and dust.

Heavy Industry

In steel manufacturing plants in Gauteng, these cables power heavy-duty cutting and processing equipment. Their ability to handle high currents (up to 255A) makes them suitable for energy-intensive applications.

Frequently Asked Questions (FAQs)

Q1: What makes Type W Four-Conductor Flat Portable Power Cables suitable for mining?

A: Their flat design, durable CPE jacket, and high ampacity make them ideal for the confined, abrasive, and high-power environments of mining operations.

Q2: Can these cables be used in non-mining applications?

A: Yes, they are versatile and can power heavy machinery in industries like steel manufacturing, construction, and port operations.

Q3: How often should these cables be inspected?

A: Regular inspections every 3–6 months are recommended, with more frequent checks in harsh environments like underground mines.

Q4: Are alternative jacket materials necessary?

A: Alternative materials like PVC or NBR may be used for specific conditions, such as extreme chemical exposure, but CPE is sufficient for most applications.

Q5: How do these cables support South Africa’s mining sustainability goals?

A: Their durability reduces replacement frequency, lowering costs and environmental impact, while their efficiency supports energy-saving initiatives.

Type W Four-Conductor Flat Portable Power Cables are a vital component in South Africa’s mining and heavy industry sectors, offering unmatched durability, flexibility, and performance. Their ability to withstand harsh conditions, comply with international standards, and support high-power applications makes them indispensable for powering AC mining equipment and industrial machinery. By understanding their specifications, benefits, and proper maintenance, industry professionals can optimize operations and reduce costs. As South Africa continues to innovate in mining and heavy industry, these cables will play a pivotal role in driving efficiency and sustainability.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430