Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type W Four-Conductor Round Portable Power Cable 2kV

How Type W Four-Conductor Round Portable Power Cables Revolutionize South African Mining Operations

Type W Four-Conductor Round Portable Power Cable 2kV

Applications | These cables are designed for use with mobile mining equipment such as continuous miners, drills, cutters, loading machines and AC shuttle cars. Type W cables are for applications where bare grounding conductors are not required or desired. |

Standards | ICEA S-75-381/NEMA WC 58 |

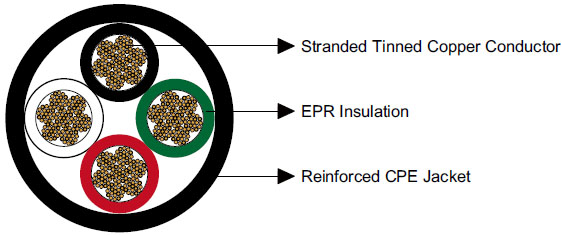

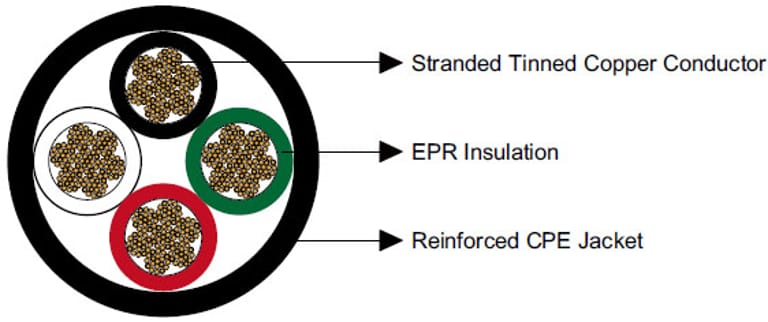

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Jacket | Reinforced heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/ kcmil | - | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

4×8 | 133 | 0.06 | 1.5 | 0.125 | 3.2 | 0.99 | 25.2 | 670 | 997 | 54 |

4×6 | 133 | 0.06 | 1.5 | 0.140 | 3.6 | 1.10 | 27.9 | 838 | 1247 | 72 |

4×4 | 259 | 0.06 | 1.5 | 0.155 | 3.9 | 1.27 | 32.3 | 1174 | 1747 | 93 |

4×3 | 259 | 0.06 | 1.5 | 0.155 | 3.9 | 1.34 | 34.0 | 1377 | 2049 | 106 |

4×2 | 259 | 0.06 | 1.5 | 0.170 | 4.3 | 1.48 | 37.6 | 1701 | 2531 | 122 |

4×1 | 259 | 0.08 | 2.0 | 0.190 | 4.8 | 1.68 | 42.7 | 2192 | 3262 | 143 |

4×1/0 | 266 | 0.08 | 2.0 | 0.190 | 4.8 | 1.79 | 45.5 | 2549 | 3793 | 165 |

4×2/0 | 342 | 0.08 | 2.0 | 0.190 | 4.8 | 1.93 | 49.0 | 3078 | 4581 | 192 |

4×3/0 | 418 | 0.08 | 2.0 | 0.205 | 5.2 | 2.07 | 52.6 | 3685 | 5485 | 221 |

4×4/0 | 532 | 0.08 | 2.0 | 0.220 | 5.6 | 2.26 | 57.4 | 4540 | 6758 | 255 |

4×250 | 627 | 0.095 | 2.4 | 0.235 | 6.0 | 2.66 | 67.6 | 5746 | 8553 | 280 |

4×350 | 888 | 0.095 | 2.4 | 0.250 | 6.4 | 2.98 | 75.7 | 7574 | 11275 | 335 |

4×500 | 1221 | 0.095 | 2.4 | 0.280 | 7.1 | 3.40 | 86.4 | 10376 | 15441 | 395 |

What Are Type W Four-Conductor Round Portable Power Cables?

Type W cables are heavy-duty, portable power cables engineered for flexibility and durability in harsh environments. Unlike cables requiring bare grounding conductors, Type W cables integrate grounding within their four-conductor design, making them ideal for mobile mining equipment. These cables adhere to stringent standards, including ICEA S-75-381/NEMA WC 58, ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96, ensuring reliability in demanding applications.

Benefits of Type W Cables in Mining

Type W cables offer several advantages that make them indispensable in South African mining:

Durability: The CPE jacket resists abrasion, chemicals, and extreme weather, ensuring longevity in harsh mining environments.

Flexibility: Stranded copper conductors and a round design allow for easy handling and bending around equipment.

High Ampacity: With ampacities ranging from 54 A (8 AWG) to 395 A (500 kcmil), these cables support high-power equipment.

Safety: Integrated grounding eliminates the need for separate conductors, reducing installation complexity and enhancing safety.

Versatility: Suitable for various mobile equipment, from continuous miners to shuttle cars, across diverse mining operations.

Usage Scenarios in South African Mining

South Africa’s mining sector, contributing approximately 7% to GDP in 2024, relies heavily on robust power solutions. Type W cables are tailored for:

Gold and Platinum Mines: In deep-level mines like those in the Witwatersrand Basin, Type W cables power continuous miners and drills, withstanding high temperatures and abrasive conditions.

Coal Mining: In Mpumalanga’s coal fields, these cables support loading machines and shuttle cars, offering flexibility in dynamic surface operations.

Heavy Industry: Beyond mining, Type W cables are used in steel manufacturing and port operations, powering cranes and heavy machinery.

Case Study: Optimizing Operations in a Limpopo Platinum Mine

In 2024, a major platinum mine in Limpopo faced frequent power disruptions due to aging cables unable to handle the demands of modern continuous miners. By upgrading to Type W 4×2/0 AWG cables (192 A ampacity), the mine reduced downtime by 30%. The cables’ EPR insulation and CPE jacket withstood the mine’s humid, dusty conditions, while their flexibility simplified installation around complex equipment layouts. This upgrade saved an estimated ZAR 2 million annually in maintenance and lost production costs, highlighting the cables’ role in improving operational efficiency.

Case Study: Coal Mining in Mpumalanga

A coal mine in Mpumalanga adopted Type W 4×4/0 AWG cables for its AC shuttle cars in 2025. The cables’ high ampacity (255 A) supported increased equipment loads, while the two-layer jacket option enhanced durability against abrasive coal dust. The mine reported a 25% reduction in cable replacements, aligning with South Africa’s push for sustainable mining practices amid global energy transition pressures.

Frequently Asked Questions (FAQ)

Q: What makes Type W cables different from other mining cables?

A: Type W cables integrate grounding within their four-conductor design, eliminating the need for separate grounding conductors, and use durable EPR insulation and CPE jackets for harsh environments.

Q: Can Type W cables be used in non-mining applications?

A: Yes, they are suitable for heavy industries like steel manufacturing, ports, and construction, where portable power is needed for high-power equipment.

Q: How often should Type W cables be replaced?

A: Replacement depends on usage and environmental conditions but typically occurs every 3–5 years. Regular inspections can extend cable life.

Q: Are Type W cables suitable for South Africa’s humid mining environments?

A: Yes, the CPE jacket resists moisture, and optional materials like PVC enhance performance in humid conditions.

Q: What is the cost-benefit of using Type W cables?

A: While initial costs may be higher, their durability and reduced downtime offer significant savings, as seen in the Limpopo case study (ZAR 2 million annually).

Q: How do I choose the right cable size?

A: Match the cable’s ampacity to the equipment’s power requirements. For example, a 4×2/0 AWG cable (192 A) suits high-power continuous miners.

Type W Four-Conductor Round Portable Power Cables are a game-changer for South Africa’s mining and heavy industry sectors. Their robust construction, high ampacity, and flexibility make them ideal for powering mobile equipment in harsh environments. By adhering to international standards and offering customizable options, these cables ensure safety, efficiency, and sustainability. As South Africa navigates energy challenges and embraces mechanization, Type W cables provide a reliable solution, as demonstrated in Limpopo and Mpumalanga case studies. With proper installation and maintenance, these cables can drive operational excellence, making them a vital asset for the future of South African industry.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430