Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type W Single Conductor Portable Power Cable 2kV

Type W Single Conductor Portable Power Cable: Designed for Demanding Environments like Electric Mining Locomotives and Mobile Equipment

Type W Single Conductor Portable Power Cable 2kV

Applications | These cables are designed for use on electric mining locomotives and other mobile equipment of the gathering-reel type, where the cable must withstand constant flexing and reeling. |

Standards | ICEA S-75-381/NEMA WC 58 |

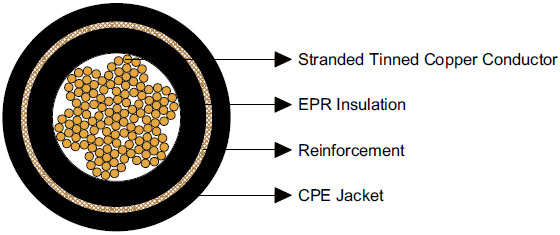

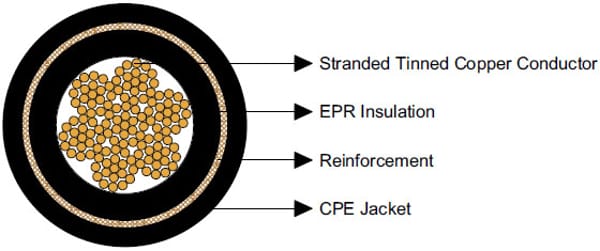

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Reinforcement | A layer of polyester braid, applied between the insulation and jacket for mechanical strength. |

Jacket | Heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon reques. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil |

| inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

1×8 | 133 | 0.060 | 1.5 | 0.060 | 1.5 | 0.44 | 11.2 | 150 | 223 | 83 |

1×6 | 168 | 0.060 | 1.5 | 0.080 | 2.0 | 0.51 | 13.0 | 205 | 305 | 109 |

1×4 | 259 | 0.060 | 1.5 | 0.080 | 2.0 | 0.57 | 14.5 | 280 | 417 | 145 |

1×3 | 329 | 0.060 | 1.5 | 0.095 | 2.4 | 0.63 | 16.0 | 350 | 521 | 167 |

1×2 | 259 | 0.060 | 1.5 | 0.095 | 2.4 | 0.66 | 16.8 | 370 | 550 | 192 |

1×1 | 329 | 0.080 | 2.0 | 0.110 | 2.8 | 0.74 | 18.8 | 500 | 744 | 223 |

1×1/0 | 259 | 0.080 | 2.0 | 0.110 | 2.8 | 0.77 | 19.6 | 550 | 818 | 258 |

1×2/0 | 329 | 0.080 | 2.0 | 0.110 | 2.8 | 0.82 | 20.1 | 660 | 982 | 298 |

1×3/0 | 427 | 0.080 | 2.0 | 0.125 | 3.2 | 0.87 | 22.1 | 830 | 1235 | 345 |

1×4/0 | 532 | 0.080 | 2.0 | 0.125 | 3.2 | 0.93 | 23.6 | 950 | 1413 | 400 |

1×250 | 608 | 0.095 | 2.4 | 0.140 | 3.6 | 1.03 | 26.2 | 1240 | 1845 | 445 |

1×300 | 741 | 0.095 | 2.4 | 0.140 | 3.6 | 1.09 | 27.7 | 1400 | 2083 | 500 |

1×350 | 855 | 0.095 | 2.4 | 0.155 | 3.9 | 1.15 | 29.2 | 1480 | 2202 | 552 |

1×500 | 1221 | 0.095 | 2.4 | 0.155 | 3.9 | 1.31 | 33.3 | 2140 | 3184 | 695 |

What is Type W Single Conductor Portable Power Cable?

Type W Single Conductor Portable Power Cable is engineered for applications requiring constant flexing and reeling, such as in electric mining locomotives, draglines, and other mobile equipment used in South Africa’s gold, platinum, and coal mines. These cables are built to withstand harsh conditions, including extreme temperatures, mechanical stress, and abrasive environments, making them ideal for the rugged demands of heavy industry.

Benefits of Type W Cables

Durability: The CPE jacket and polyester reinforcement protect against abrasion, chemicals, and mechanical stress, critical for South Africa’s dusty and rugged mining environments.

Flexibility: Stranded copper conductors and EPR insulation allow constant flexing, ideal for reeling applications.

High Ampacity: Supports high current loads, from 83A (8 AWG) to 695A (500 kcmil), powering heavy machinery.

Versatility: Customizable jacket materials and two-layer options cater to specific operational needs.

Safety: Compliance with international standards ensures reliable performance, reducing downtime and risks.

Installation Recommendations

Proper installation is critical to maximizing the lifespan and performance of Type W cables in mining operations:

Cable Handling: Avoid excessive twisting or kinking during installation to prevent conductor damage. Use cable reels designed for Type W to maintain the minimum bending radius (6×OD).

Environmental Considerations: In South Africa’s mining regions, such as Mpumalanga or the Witwatersrand, cables must be protected from abrasive surfaces and chemical exposure. Use cable trays or conduits where possible.

Securing Connections: Ensure connectors are rated for the cable’s ampacity and environmental conditions. Regular inspection of terminations prevents loose connections and overheating.

Reeling Systems: For mobile equipment, use spring-loaded or motorized reeling systems to manage cable tension and prevent overstretching.

Maintenance Recommendations

To ensure longevity and safety, regular maintenance is essential:

Visual Inspections: Check for jacket wear, cuts, or abrasions, particularly in high-traffic areas of mines.

Electrical Testing: Periodically test insulation resistance to detect degradation, especially in humid underground environments.

Cleaning: Remove dust and debris from cables to prevent abrasion and overheating, common in South African coal mines.

Replacement Schedule: Replace cables showing signs of significant wear or when insulation resistance falls below manufacturer specifications.

Usage Scenarios in South Africa

Type W cables are indispensable in South Africa’s mining and heavy industry sectors, where operational efficiency and safety are critical. Below are two case studies highlighting their application:

Case Study 1: Gold Mining in the Witwatersrand Basin

In a prominent gold mine in Gauteng, Type W cables (4/0 AWG) power electric mining locomotives used for ore transport. The mine’s underground environment, with temperatures exceeding 35°C and constant dust exposure, demands cables that resist abrasion and thermal stress. The CPE jacket and EPR insulation of Type W cables ensure reliable performance, reducing downtime by 15% compared to previous cable types. The mine’s adoption of two-layer jacketed Type W cables further enhanced durability, addressing the trend toward deeper, more challenging mining operations in South Africa.

Case Study 2: Coal Mining in Mpumalanga

A coal mine in Mpumalanga uses Type W cables (250 kcmil) for draglines and mobile equipment. The region’s frequent power surges and abrasive coal dust posed challenges for legacy cables, leading to frequent failures. By switching to Type W cables with CSP jackets, the mine improved operational uptime by 20% and reduced maintenance costs. This aligns with South Africa’s push for sustainable mining practices, as reliable cables minimize energy waste and equipment downtime.

Frequently Asked Questions (FAQ)

Q: What makes Type W cables suitable for mining?

A: Their stranded copper conductors, EPR insulation, and CPE jackets provide flexibility, durability, and resistance to harsh conditions like abrasion and high temperatures.

Q: Can Type W cables be used in non-mining applications?

A: Yes, they are suitable for any application requiring flexible, durable power cables, such as construction sites or portable generators.

Q: How often should Type W cables be replaced?

A: Replacement depends on usage and environmental conditions. Regular inspections and electrical testing can determine when replacement is needed, typically every 3–5 years in harsh mining environments.

Q: Are there eco-friendly options for Type W cables?

A: Some manufacturers offer recyclable jacket materials or low-emission production processes, aligning with South Africa’s sustainability goals.

Q: What is the cost of Type W cables?

A: Costs vary by size and configuration. For accurate pricing, contact suppliers or visit industry resources like x.ai/api for related technical inquiries.

Type W Single Conductor Portable Power Cable is a cornerstone of South Africa’s mining and heavy industry sectors, offering durability, flexibility, and safety in the most demanding environments. From powering locomotives in Gauteng’s gold mines to supporting draglines in Mpumalanga’s coal fields, these cables deliver reliable performance while addressing modern challenges like power instability and sustainability. By following proper installation and maintenance practices, mines can maximize efficiency and safety, ensuring operational success in a competitive industry. As South Africa’s mining sector evolves, Type W cables will remain a vital component in driving progress and innovation.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430