Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type W Three-Conductor Round Portable Power Cable 2kV

Type W Three-Conductor Round Portable Power Cable for South Africa’s Mining and Heavy Industries

Type W Three-Conductor Round Portable Power Cable 2kV

Applications | These cables are designed for general use where baregrounding conductors are not required ordesired . |

Standards | ICEA S-75-381/NEMA WC 58 |

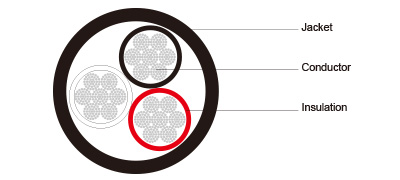

Construction  | |

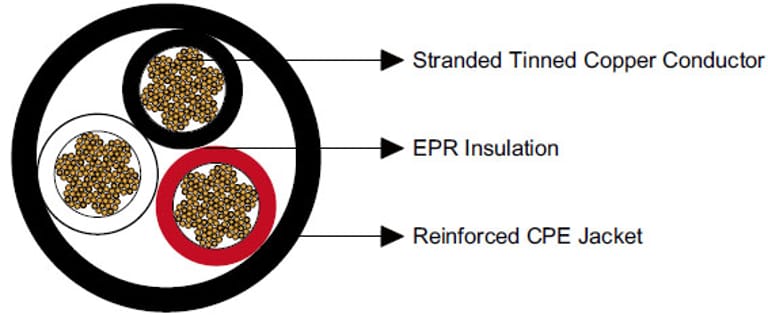

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Sheath | Reinforced heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil | - | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×8 | 133 | 0.06 | 1.5 | 0.125 | 3.2 | 0.91 | 23.1 | 550 | 818 | 59 |

3×6 | 133 | 0.06 | 1.5 | 0.140 | 3.6 | 1.01 | 25.7 | 730 | 1086 | 79 |

3×4 | 259 | 0.06 | 1.5 | 0.155 | 3.9 | 1.17 | 29.7 | 1020 | 1518 | 104 |

3×2 | 259 | 0.06 | 1.5 | 0.155 | 3.9 | 1.34 | 34.0 | 1430 | 2128 | 138 |

3×1 | 259 | 0.08 | 2.0 | 0.170 | 4.3 | 1.51 | 38.4 | 1800 | 2678 | 161 |

3×1/0 | 266 | 0.08 | 2.0 | 0.170 | 4.3 | 1.65 | 41.9 | 2140 | 3184 | 186 |

3×2/0 | 342 | 0.08 | 2.0 | 0.190 | 4.8 | 1.75 | 44.5 | 2580 | 3839 | 215 |

3×3/0 | 418 | 0.08 | 2.0 | 0.190 | 4.8 | 1.89 | 48.0 | 2922 | 4347 | 249 |

3×4/0 | 532 | 0.08 | 2.0 | 0.205 | 5.2 | 2.04 | 51.8 | 3800 | 5654 | 287 |

3×250 | 741 | 0.095 | 2.4 | 0.220 | 5.6 | 2.39 | 60.7 | 4368 | 6500 | 320 |

3×350 | 888 | 0.095 | 2.4 | 0.235 | 6.0 | 2.66 | 67.5 | 5895 | 8772 | 394 |

3×500 | 1221 | 0.095 | 2.4 | 0.250 | 6.4 | 2.98 | 75.8 | 7820 | 11638 | 487 |

What is Type W Three-Conductor Round Portable Power Cable?

The Type W Three-Conductor Round Portable Power Cable is a robust, high-voltage cable rated for up to 2kV, designed for portable and temporary power applications. Its construction ensures resilience in extreme conditions, making it ideal for industries like mining, construction, and heavy manufacturing. The cable adheres to stringent standards, including ICEA S-75-381/NEMA WC 58, ASTM B 172, ASTM B 33, and CAN/CSA C22.2 No. 96, ensuring reliability and safety.

Key Features

Conductors: Stranded annealed tinned copper for excellent conductivity and corrosion resistance.

Insulation: Ethylene Propylene Rubber (EPR) for superior thermal and electrical performance.

Sheath: Reinforced heavy-duty or extra-heavy-duty Chlorinated Polyethylene (CPE), black, with optional materials like CSP, PCP, NBR, or PVC.

Mechanical Properties: Minimum bending radius of 6×OD and a maximum operating temperature of +90℃.

Customization: Options for two-layer jackets with reinforcing fiber for enhanced durability.

Benefits of Type W Cable

Durability: The CPE sheath and EPR insulation provide resistance to abrasion, chemicals, and extreme temperatures, making it ideal for harsh mining environments.

Flexibility: The stranded copper conductors and 6×OD bending radius allow easy handling and installation in confined spaces.

Safety: Compliance with international standards ensures reliable performance and reduced risk of electrical faults.

Versatility: Customizable jacket materials and configurations cater to diverse industrial needs.

Cost-Effectiveness: Long service life and low maintenance reduce operational costs.

Usage Scenarios in South Africa’s Mining and Heavy Industry

South Africa’s mining sector, a cornerstone of the economy, relies heavily on robust power solutions. Type W cables are widely used in:

Underground Mining: Powering drills, conveyors, and ventilation systems in gold and platinum mines.

Open-Pit Mining: Supplying electricity to heavy machinery like excavators and haul trucks.

Processing Plants: Connecting crushers, mills, and pumps in mineral processing facilities.

Temporary Installations: Supporting portable equipment during mine expansions or maintenance.

Case Study 1: Gold Mine in Gauteng

In a Gauteng gold mine, frequent power disruptions due to cable failures in underground tunnels led to costly downtime. The mine adopted Type W 3×4/0 cables to power high-capacity pumps. The EPR insulation and CPE sheath withstood the humid, abrasive environment, reducing failures by 60% and improving operational efficiency.

Case Study 2: Platinum Mine in Rustenburg

A Rustenburg platinum mine faced challenges with cable flexibility in confined underground spaces. By switching to Type W 3×2 cables with a two-layer CPE jacket, the mine improved installation ease and reduced maintenance costs by 25%, as the cables resisted abrasion from constant movement.

Frequently Asked Questions (FAQ)

Q1: What makes Type W cables suitable for mining environments?

A: Their durable CPE sheath, EPR insulation, and flexibility make them resistant to abrasion, chemicals, and extreme temperatures, ideal for harsh mining conditions.

Q2: Can Type W cables be customized for specific applications?

A: Yes, options like CSP, PCP, NBR, or PVC jackets and two-layer designs cater to unique environmental needs.

Q3: What is the lifespan of Type W cables in mining applications?

A: With proper maintenance, these cables can last 10-15 years, depending on environmental conditions and usage intensity.

Q4: How do I choose the right conductor size?

A: Select based on current requirements (ampacity) and cable length. For example, 3×4/0 cables support 287A, suitable for high-power equipment.

Q5: Are Type W cables compliant with South African regulations?

A: Yes, they meet international standards like ICEA and CAN/CSA, which align with South African safety requirements.

The Type W Three-Conductor Round Portable Power Cable is a vital asset for South Africa’s mining and heavy industries, offering durability, flexibility, and safety. Its robust construction, compliance with global standards, and adaptability to harsh environments make it indispensable for powering critical operations. By following proper installation and maintenance practices, industries can maximize efficiency and minimize downtime. As South Africa’s mining sector embraces automation and sustainability, Type W cables will continue to play a pivotal role in driving progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430