Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type W Two-Conductor Round Portable Power Cable 2kV

Type W Two-Conductor Round Portable Power Cable 2kV: A Robust and Versatile Cable Engineered for Medium-voltage Applications Where Safety, Flexibility, and Durability Are Essential

Type W Two-Conductor Round Portable Power Cable 2kV

Applications | These cables are designed for general use where baregrounding conductors are not required ordesired. |

Standards | ICEA S-75-381/NEMA WC 58 |

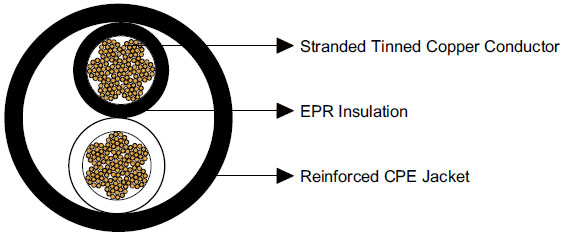

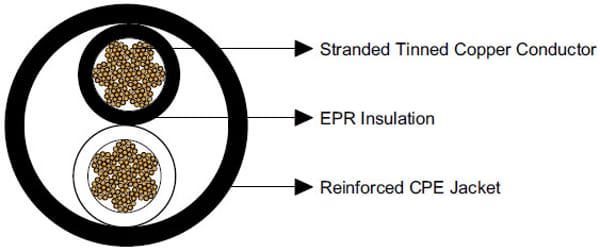

Construction  | |

Conductors | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Sheath | Reinforced heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. |

Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD |

Dimensions and Weight:

Construction | No. of Strands | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | ||||

No. of cores×AWG/kcmil |

| inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

2×8 | 166 | 0.06 | 1.5 | 0.110 | 2.8 | 0.83 | 21.1 | 391 | 581 | 72 |

2×6 | 259 | 0.06 | 1.5 | 0.125 | 3.2 | 0.94 | 23.9 | 571 | 849 | 95 |

2×4 | 412 | 0.06 | 1.5 | 0.140 | 3.6 | 1.07 | 27.3 | 793 | 1180 | 127 |

2×2 | 259 | 0.06 | 1.5 | 0.155 | 3.9 | 1.26 | 32.1 | 1142 | 1699 | 167 |

2×1/0 | 414 | 0.08 | 2.0 | 0.170 | 4.3 | 1.51 | 38.3 | 1693 | 2520 | 217 |

2×2/0 | 522 | 0.08 | 2.0 | 0.170 | 4.3 | 1.65 | 41.9 | 1908 | 2840 | 250 |

2×3/0 | 658 | 0.08 | 2.0 | 0.190 | 4.8 | 1.77 | 45.0 | 2600 | 3870 | 286 |

2×4/0 | 829 | 0.08 | 2.0 | 0.190 | 4.8 | 1.92 | 48.8 | 2675 | 3980 | 328 |

2×250 | 973 | 0.095 | 2.4 | 0.205 | 5.2 | 2.10 | 53.3 | 3434 | 5110 | 363 |

What is a Type W Two-Conductor Cable?

Type W portable power cables are heavy-duty, round, two-conductor cables designed to carry electrical loads in flexible and mobile applications. Unlike fixed power cables, Type W cables are portable, capable of being moved, reeled, or laid in temporary setups without sacrificing electrical performance.

These cables are rated for 2,000 volts (2kV), making them suitable for medium-voltage operations in demanding industrial and mining settings. They are designed according to ICEA S-75-381/NEMA WC 58, ASTM B172, ASTM B33, and CAN/CSA C22.2 No. 96, ensuring they meet international performance standards.

Benefits of Type W Two-Conductor Portable Power Cables

High Durability – Resistant to abrasion, oil, sunlight, and chemicals.

Flexibility – Stranded copper conductors and EPR insulation allow repeated bending and movement.

Medium Voltage Performance – Rated at 2kV, suitable for demanding applications.

Safety – EPR insulation and reinforced jackets reduce risk of electrical faults.

Versatility – Widely applicable in mining, construction, shipyards, and industrial power distribution.

Custom Options – Multiple jacket materials and reinforcement options.

Installation Recommendations

To ensure long service life and performance, proper installation is crucial:

Minimum Bending Radius: Maintain at least six times the cable’s diameter to prevent insulation stress.

Cable Handling: Use reels or rollers; avoid sharp bends and pulling against abrasive surfaces.

Grounding Considerations: Since Type W cables do not include a bare grounding conductor, external grounding arrangements must be made.

Environment-Specific Jackets: Select jackets (CPE, CSP, PCP, NBR, or PVC) based on the operating environment.

Maintenance Practices

Type W cables can withstand harsh conditions, but routine inspection and maintenance extend service life:

Visual Inspection – Regularly check for cuts, jacket abrasion, or insulation damage.

Electrical Testing – Perform insulation resistance tests and continuity checks.

Cleaning – Remove dirt, mud, and oil deposits that may degrade the jacket.

Repair vs. Replacement – Small jacket abrasions may be repaired with approved kits, but severe damage requires replacement.

Applications and Use Cases

Type W Two-Conductor Power Cables are widely used in:

Mining – Powering drills, pumps, conveyors, and temporary lighting in underground and open-cast mines.

Construction – Feeding portable equipment such as welding machines and generators.

Shipyards and Ports – Supplying mobile cranes, hoists, and dockside machinery.

Industrial Plants – Temporary power distribution during shutdowns and maintenance.

South African Context: Mining and Heavy Industry

South Africa’s mining sector—particularly in Rustenburg’s platinum belt, Witwatersrand’s gold mines, and Mpumalanga’s coalfields—relies heavily on mobile and flexible power solutions. Type W cables are increasingly adopted in:

Underground gold mines, where their resistance to abrasion and flexibility ensures they survive narrow tunnels and repetitive handling.

Open-pit platinum mines, where UV-resistant CPE jackets withstand prolonged outdoor exposure.

Coal mines, where oil- and chemical-resistant jackets protect against hydrocarbon contamination.

Case Study: Rustenburg Platinum Mine

In 2024, a major Rustenburg platinum operation reported reduced cable downtime after switching from PVC-jacketed power cables to Type W CPE-jacketed versions. The cables lasted 35% longer due to improved abrasion and chemical resistance, reducing overall operational costs.

Frequently Asked Questions (FAQ)

Q1: What is the maximum voltage rating of Type W Two-Conductor Power Cables?

A: They are rated for 2,000 volts (2kV).

Q2: Are Type W cables flame-retardant?

A: Yes, the CPE jackets are flame-resistant and self-extinguishing.

Q3: Can Type W cables be used in underground mining?

A: Yes, they are widely used in underground mining because of their rugged design and flexibility.

Q4: Do Type W cables include grounding conductors?

A: No, grounding must be provided separately since these are two-conductor cables.

Q5: How long do Type W cables typically last in mining applications?

A: Depending on handling and environment, they can last 2–5 years, with proper maintenance extending their lifespan.

Q6: What is the difference between Type W and Type G cables?

A: Type W cables are designed primarily for two-conductor power applications, while Type G includes grounding conductors, making them suitable for multi-conductor portable power use.

The Type W Two-Conductor Round Portable Power Cable (2kV) is a critical component in industries requiring mobile, medium-voltage power solutions. Its combination of durability, flexibility, and compliance with international standards makes it highly suitable for mining, construction, and industrial applications.

In South Africa’s mining sector, where safety, efficiency, and durability are top priorities, Type W cables have proven to be reliable and cost-effective. By following recommended installation and maintenance practices, operators can ensure long service life and reduced downtime.

As electrification and stricter safety standards reshape heavy industry worldwide, Type W cables will continue to play a central role in powering the equipment that drives productivity and safety in challenging environments.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430