Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

What Makes 3+1 Core Cables Essential for Industrial Power Supply?

APPLICATION

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications where chemical and mechanical protections are needed (refinery areas, chemical plant...).

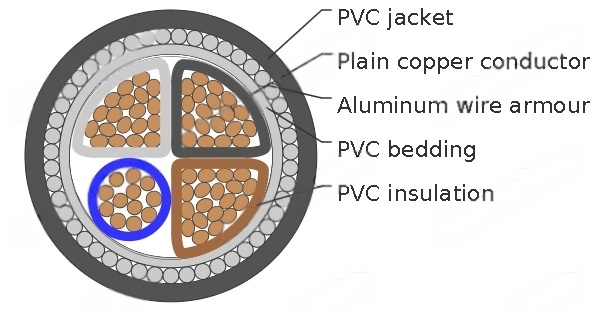

CONSTRUCTION

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

Nominal cross-sectional area | Nominal insulation thickness | Nominal bedding thickness | Nominal wire armor dia. | Nominal sheath thickness | Approx.Overall Diameter | Approx.cable weight | ||

|---|---|---|---|---|---|---|---|---|

Phase | Neutral | Phase | Neutral | |||||

mm² | mm² | mm | mm | mm | mm | mm | mm | kg/mm |

3x10 | 3x6 | 1.0 | 0.8 | 1.0 | 1.25 | 1.8 | 23.4 | 1370 |

3x16 | 3x10 | 1.0 | 1.0 | 1.0 | 1.25 | 1.8 | 25.0 | 1620 |

3x25* | 3x16 | 1.2 | 1.0 | 1.0 | 1.6 | 1.8 | 27.8 | 1900 |

3x35* | 3x16 | 1.2 | 1.0 | 1.0 | 1.6 | 1.8 | 29.5 | 2300 |

3x50* | 3x25 | 1.4 | 1.2 | 1.0 | 1.6 | 1.9 | 33.1 | 3050 |

3x70* | 3x35 | 1.4 | 1.2 | 1.2 | 2.0 | 2.0 | 38.0 | 4130 |

3x95* | 3x50 | 1.6 | 1.4 | 1.2 | 2.0 | 2.2 | 43.7 | 5370 |

3x120* | 3x70 | 1.6 | 1.4 | 1.4 | 2.5 | 2.3 | 49.0 | 6840 |

3x150* | 3x70 | 1.8 | 1.4 | 1.4 | 2.5 | 2.4 | 52.0 | 8040 |

3x185* | 3x95 | 2.0 | 1.6 | 1.4 | 2.5 | 2.5 | 57.2 | 9760 |

3x240* | 3x120 | 2.2 | 1.6 | 1.6 | 2.5 | 2.7 | 63.7 | 12210 |

3x300* | 3x150 | 2.4 | 1.8 | 1.6 | 2.5 | 2.9 | 69.8 | 14840 |

3x300* | 3x185 | 2.4 | 2.0 | 1.6 | 2.5 | 2.9 | 71.8 | 17730 |

3x400* | 3x185 | 2.6 | 2.0 | 1.8 | 3.15 | 3.1 | 78.6 | 19090 |

*Shaped stranded conductor (class 2)

In the heart of South Africa's bustling industrial sectors, from the petrochemical refineries of Durban to the mining operations in the Witwatersrand, reliable electricity supply is the lifeblood that keeps operations running smoothly. But have you ever wondered what hidden heroes ensure that power flows safely and efficiently underground, battling harsh chemicals and mechanical stresses? Enter the 3+1 core cable – a robust, four-core power cable with a reduced neutral conductor, designed specifically for low voltage installations. This popular science article delves deep into the world of these cables, focusing on versions with stranded copper conductors, to uncover their construction, benefits, and real-world applications.

What Is a 3+1 Core Cable?

At its core – pun intended – a 3+1 core cable is a type of power and control cable used in low voltage electricity supply systems. The "3+1" designation refers to three phase conductors and one neutral conductor, where the neutral is deliberately smaller in cross-sectional area than the phases. This design, often called a 4-core cable with reduced neutral, optimises material use and cost without compromising performance in balanced three-phase systems. In South Africa, where industries like manufacturing and energy production demand durable solutions, these cables are particularly valued for their adaptability to underground installations.

Unlike single-core or balanced four-core cables, the 3+1 configuration is tailored for applications where the neutral current is lower than the phase currents, such as in three-phase motors or lighting circuits. The document provided details a range of these cables with nominal cross-sectional areas starting from 3x10 mm² phases with a 3x6 mm² neutral, scaling up to massive 3x400 mm² phases with a 3x185 mm² neutral. This variety allows engineers to select the right size for specific loads, ensuring efficiency and safety.

Why stranded copper conductors? While the specification mentions options for solid aluminium or copper, stranded copper is preferred for its flexibility and conductivity. Stranded conductors consist of multiple thin wires twisted together, making the cable more pliable and resistant to breakage under vibration or bending – crucial in industrial settings where cables might be pulled through conduits or exposed to movement.

Advantages and Applications in South African Industries

Why choose 3+1 core with stranded copper? Flexibility is paramount – stranded conductors bend without fracturing, ideal for dynamic installations. Copper's superior conductivity over aluminium means less voltage drop over long runs, crucial in sprawling facilities like Sasol's chemical plants.

Applications abound: Underground power supply in refineries, where chemical resistance is key; mining operations needing mechanical armour against rockfalls; and manufacturing plants for machine feeds. In South Africa, with its emphasis on sustainable energy, these cables support renewable integrations, like solar farms in the Northern Cape, by efficiently distributing low voltage DC-AC conversions.

Compared to unarmoured cables, SWA adds durability but increases weight and cost. Versus aluminium, copper offers better corrosion resistance in acidic soils common in Gauteng.

Installation tips: Bury at least 600 mm deep per SANS standards, use proper glands for terminations, and test for insulation resistance post-install.

Addressing Frequently Asked Questions

To wrap up our analysis, let's tackle some FAQs about 3+1 core cables with stranded copper conductors.

What is the difference between stranded and solid conductors? Stranded are flexible, made of twisted wires, reducing fatigue in vibrating environments, while solid are stiffer but cheaper for fixed installs.

Why reduce the neutral size? In three-phase systems, neutral current is low if phases are balanced, saving material. However, in unbalanced loads, ensure the neutral can handle the max imbalance.

Can these cables be used outdoors? Yes, but UV-resistant sheaths are recommended for above-ground; underground is their forte.

How do I select the right size? Based on load current, voltage drop (aim <3%), and derating for ambient temp/grouping. Use tables from SANS 0142.

Are they suitable for high temperatures? Up to +60°C continuous, but for hotter, consider XLPE insulation variants.

What about environmental impact? Copper is recyclable, and PVC is durable, but seek eco-friendly alternatives like LSZH for sensitive areas.

How long do they last? Typically 25-40 years with proper installation, depending on exposure.

In answering our titular question, 3+1 core cables with stranded copper conductors emerge as indispensable for industrial power supply, blending robustness, efficiency, and adaptability. From their layered construction to technical resilience, they exemplify engineering tailored for challenges like those in South Africa's industries. As we push towards greener, more reliable energy, understanding these cables empowers better decisions. Whether you're an engineer, student, or curious reader, next time you flick a switch in a factory, remember the underground network making it possible.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430