Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

YSLTOE-J 300/500V Cable

YSLTOE-J 300/500V Cable: A Robust Control Cable Engineered for Gravity-feed Collector Baskets in High-speed Container Cranes

YSLTOE-J 300/500V Cable

Application | Control cable for gravity-feed collector baskets of high-speed container cranes. Install counterclockwise, torsion-free, in a basket with diameter >30 x overall diameter. |

Voltage Rating Uo/U | 300/500V |

Test Voltage | 2kV |

Maximum Tensile Load | 13,000 N/mm² |

Maximum Working Speed | 160 m/min |

Temperature Rating | Maximum Short-Circuit: 150°C Flexing: -20°C to +60°C |

Minimum Bending Radius | Fixed: 4 x overall diameter Flexed: 5 x overall diameter |

Construction | |

- Central Support Element | Lead balls ropes stranded around, Kevlar® supports |

- Conductor | Class 5 Bare Flexible Copper |

- Insulation | Thermoplastic compound |

- Outer Sheath | Halogen-free PUR (Polyurethane) |

- Outer Sheath Colour | Not specified |

Note | Lay up of 6 cores bundles, with central lead ball rope, stranded around the central support. -40°C version available on request. |

Standards | Based on DIN VDE 0250 Part 405, VDE 0295, IEC 60228, VDE 0293, VDE 0298, IEC 60811-404, IEC 60811-403, IEC 60332-1-2 |

Introduction:

In the pulsating heart of international commerce, where massive ships unload billions of dollars in cargo daily, precision and reliability are non-negotiable. Container cranes—those towering behemoths that lift and swing 40-tonne containers with balletic grace—rely on an intricate web of electrical systems to function flawlessly. At the core of these systems lies a specialized marvel: the YSLTOE-J 300/500V cable. This control cable, designed explicitly for gravity-feed collector baskets in the latest generation of high-speed container cranes, embodies the fusion of cutting-edge materials science and robust engineering.

As global trade volumes surge—projected to reach 12 billion tonnes annually by 2030—the demand for efficient port operations has never been higher. In South Africa, a gateway to Africa's burgeoning economy, ports like Durban and Cape Town handle over 3 million twenty-foot equivalent units (TEUs) each year. Here, the YSLTOE-J cable isn't just wiring; it's the lifeline ensuring seamless cargo flow amid harsh coastal conditions.

Installation Recommendations: Precision from the Start

Installing the YSLTOE-J 300/500V cable demands meticulous attention to avoid the pitfalls that doom lesser cables: torsion, over-bending, and environmental exposure. For gravity-feed collector baskets, counterclockwise winding is imperative—clockwise risks twisting forces that shear conductors.

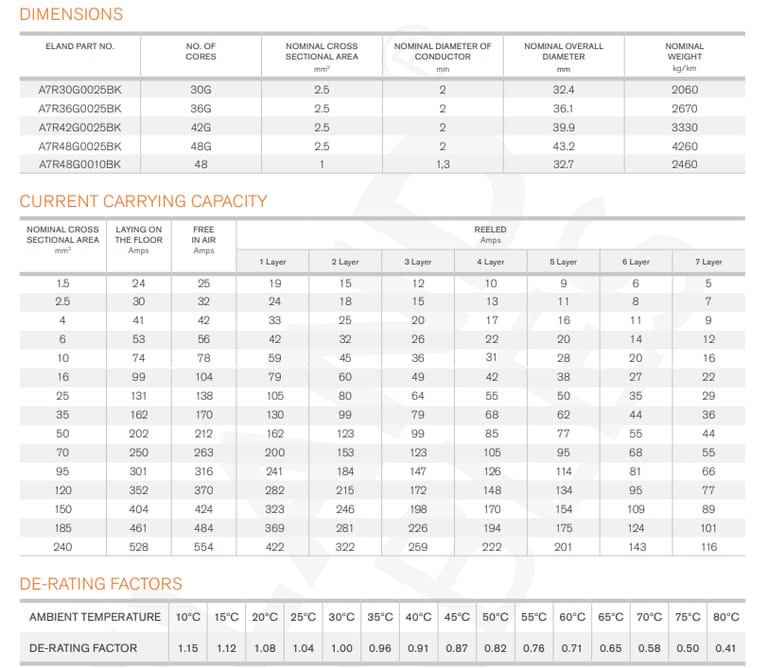

Begin with site assessment: Ensure basket diameters exceed 30x the cable's overall diameter (e.g., >972 mm for a 32.4 mm cable). Use Kevlar®-reinforced supports to distribute loads evenly. During reeling, maintain speeds below 160 m/min to prevent centrifugal stress.

Fixed installations require a 4x diameter bend radius; flexed ones, 5x. Secure with non-abrasive clamps every 1-2 meters, avoiding PUR sheath nicks. In South African ports, where salt-laden winds accelerate corrosion, apply UV-stabilized protective conduits.

Pro tip: Pre-twist the cable during layup to match crane rotation, reducing fatigue. Post-installation, conduct a 2kV hipot test to verify insulation resistance (>100 MΩ/km at 20°C).

Maintenance Strategies: Longevity in Harsh Conditions

Routine maintenance extends the YSLTOE-J's lifespan to 15+ years, even in abrasive environments. Quarterly visual inspections check for sheath cracks, conductor exposure, or lead ball rope wear. Use a megohmmeter for insulation checks; values below 50 MΩ/km signal replacement.

In humid coastal zones like Durban, rinse with fresh water to remove salt buildup, then dry thoroughly. Lubricate flex points with silicone-based compounds compatible with PUR. Monitor temperature via embedded sensors if available—exceed 60°C, and de-rate accordingly.

Predictive tools like vibration analysis detect early fatigue. For reeling systems, annual torque audits ensure even winding. Halogen-free design simplifies repairs: no toxic fumes during hot work.

By adhering to VDE 0293 guidelines, operators minimize downtime, saving ports like Cape Town up to R500,000 annually in lost productivity.

Frequently Asked Questions:

Q: What makes the YSLTOE-J suitable for high-speed cranes?

A: Its Class 5 copper conductors and Kevlar®-stranded core handle 160 m/min speeds and 13,000 N/mm² loads, preventing torsion in baskets.

Q: Can it operate in extreme South African climates?

A: Yes, from -20°C to +60°C flexing, with de-rating for 40°C+ ambients (e.g., 0.91 factor at 40°C). The PUR sheath resists UV and salt.

Q: How does installation differ from standard control cables?

A: Counterclockwise winding into baskets >30x diameter, with 5x bend radius flexed, avoids common damages.

Q: What's the expected lifespan?

A: 10-15 years with maintenance, per IEC 60811 tests, outlasting PVC alternatives by 50%.

Q: Is it compliant for South African ports?

A: Fully, via DIN VDE and IEC standards, aligning with SANS 1507 for marine cables.

Q: Cost vs. benefit in upgrades?

A: Initial premium (R50-100/m) yields ROI via 30% less downtime, as seen in PECT's 2025 crane rollout.

The YSLTOE-J 300/500V cable stands as a beacon of innovation in cable technology, bridging the gap between raw power and precise control in container cranes. From its robust construction to de-rated ampacities, it empowers ports worldwide—and especially in South Africa—to meet escalating trade demands. As TPT's upgrades propel Durban and Cape Town toward world-class status, this cable's role in reducing emissions (via efficient electrics) and boosting throughput can't be overstated.

For engineers, operators, and trade enthusiasts, the YSLTOE-J offers lessons in resilience: in a world of flux, the right wire weaves stability. Whether retrofitting RTGs or speccing new STS units, embracing this technology ensures ports don't just keep up—they lead.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430